Drying and grinding of hydrolytic lignin

In hydrolytic industry they receive so called powdered hydrolytic lignin. In cellulose production water-soluble forms of lignin are generated. There are two main pulping technologies: more widespread - kraft process (alkaline), less widespread - sulfite digestion (acid). Lignin received in sulfate production is called sulfate lignin. In sulfite production sulfite lignins liquors (lignosulphonates) are received.

The problem of industrial recycling is depend on its nature, a great quantity of variants of structural components and connections between them, and also on instability of this natural polymer, which changes its features as the result of chemical or thermal effects irreversibly. Not natural protolignin is in the waste of enterprises, but, substantially, modified lignin-containing substances of mixtures of substances, which have great chemical and biological activities. Moreover, they are polluted by other substances.

Hydrolytic lignin is a mass with humidity 65-70%. At the same time hydrolytic lignin differs by its composition from sawdust, which consists of up to 20% mineral touches of different origin, dust, as an example. Therefore, methods of its recycling and disposal areas are quite different from recycling methods of other wood waste. Common dosage and thermal treatment in the presence of inertial heat carrier, for example, bitumen, shows that acceptable result is achievable only at minimum dosage of hydrolytic lignin – not more than 10%. Using "by analogy" with wood waste also meets some specific features of hydrolytic lignin. It’s necessary to notice characteristics of hydrolytic lignin:

- Relatively high content of inorganic hydrolyzing agent, most sulfuric acid (1.5% wt.);

- High aromaticity in this mixture of biopolimers;

- Polydispersity and humidity.

Polydispersity of hydrolytic lignin in combination with high humidity determines the complexity of the drying process. For efficient drying and grinding of hydrolytic lignin by specialists of "Research and Production Company PARMATECH" aerodynamic dispergator is used. As the result, dry powder of hydrolytic lignin is received.

| Raw material - hydrolytic lignin |

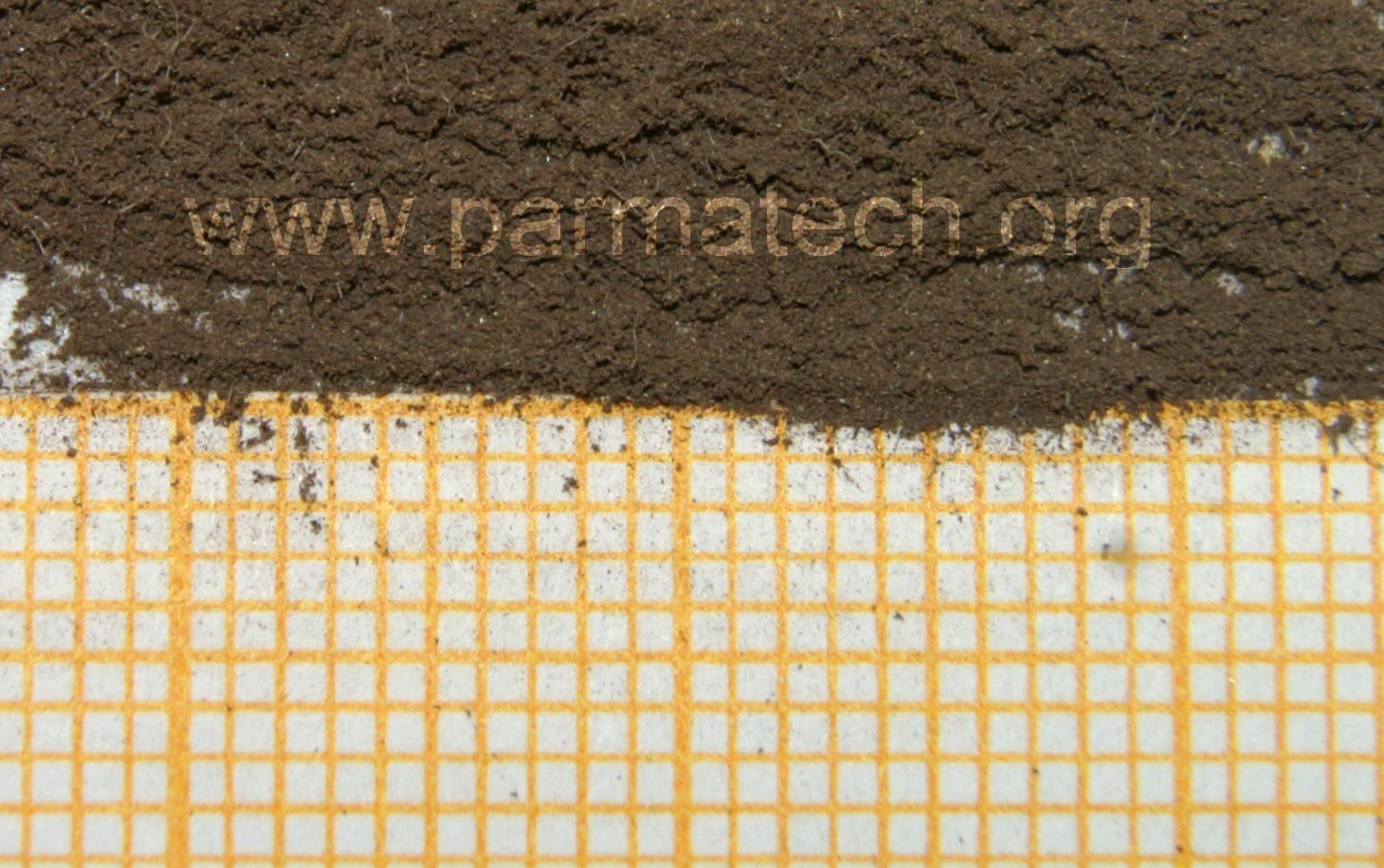

Recycling result – dry lignin, powder. |

|

|

Received product doesn’t contain extraneous inclusions.